Industrial rotary systems have evolved significantly. Whereas a few years ago, transmitting power alone was sufficient, current architectures now integrate sensors, control systems, cameras, actuators, and high-speed industrial communication networks. A central challenge in these systems today is to ensure continuous and reliable data transmission between a stationary and a rotating part, without interruption, signal degradation, and over long operating periods.

Contactless Slip Ring solutions are particularly relevant in this context, especially for applications requiring fast and deterministic industrial Ethernet communication.

From mechanical slip rings to contactless solutions: a natural evolution

Mechanical slip rings have long been the standard solution for transmitting power and signals in rotary systems. They proved their effectiveness in numerous industrial applications, based on physical contacts (brushes and conductive tracks).

However, with increasing data rates and the widespread adoption of industrial networks, these technologies face certain limitations:

- mechanical wear due to friction

- regular maintenance requirements

- generation of electrical noise

- increased sensitivity in electrically challenging industrial environments.

These constraints have led engineers to explore alternative solutions capable of maintaining stable transmission quality over time, regardless of rotational speed or operating conditions. Contactless transmission technologies are a natural continuation of this evolution.

What is a Contactless Slip Ring, beyond the product definition?

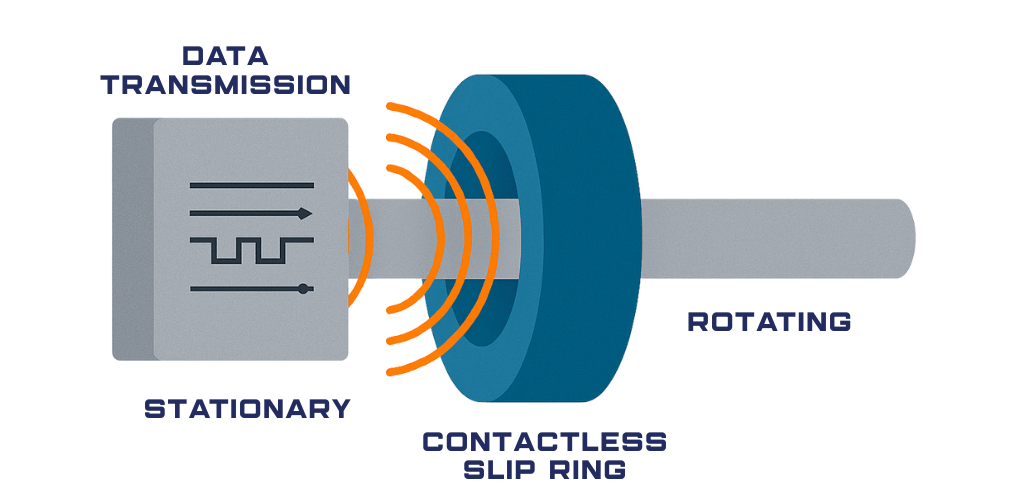

A Contactless Slip Ring enables data transmission between a stationary and a rotating part without direct physical contact between transmission elements.

Unlike traditional mechanical solutions, this approach eliminates friction, wear, and heating associated with contacts, ensuring continuous, stable, and reproducible transmission over the system’s lifetime.

Beyond the technological aspect, the Contactless Slip Ring represents a true paradigm shift in the design of modern rotary systems. Transmission reliability is no longer dependent on mechanical interfaces subject to wear but on an architecture designed for longevity and consistent performance.

Why contactless technology is particularly suited for industrial Ethernet networks

Industrial Ethernet networks (Fast Ethernet, Gigabit Ethernet, and real-time variants) impose specific constraints:

- controlled, deterministic latency

- continuous full-duplex transmission

- signal regeneration thanks processing electronics

- reliable data synchronization.

In this context, any micro-interruption or contact degradation can impact overall system performance. Contactless solutions meet these requirements by providing stable and uninterrupted transmission, even at high rotational speeds.

This approach is particularly relevant when:

- data volumes are significant

- communication continuity is critical

- the system must operate over long periods without intervention

Demanding industrial environments : when contactless is relevant

Contactless Slip Rings are not intended to replace all mechanical slip rings but to address well-defined use cases, particularly when operating conditions are especially demanding.

They are typically deployed in environments characterized by:

- significant electrical disturbances

- continuous mechanical vibrations

- prolonged rotation cycles

- high maintenance constraints or limited access

Such conditions are commonly found in sectors including:

- wind energy

- food and beverage processing

- industrial robotics

- defense vehicles and specialized equipment

System integration: key considerations

Selecting a Contactless Slip Ring is primarily based on a global system analysis. Key criteria include:

- required data rate: 100 Mb/s, 1 Gb/s, or higher depending on network architecture

- communication protocols used (real-time industrial Ethernet)

- environmental conditions: temperature, vibrations, operating duration

- mechanical constraints: bore size, space, modularity

- expected maintenance and service life

- compatibility with copper or fiber optic interfaces

A customized approach is often necessary to ensure optimal integration into the final system.

Everaxis Contactless Slip Rings: illustrating industrial implementation

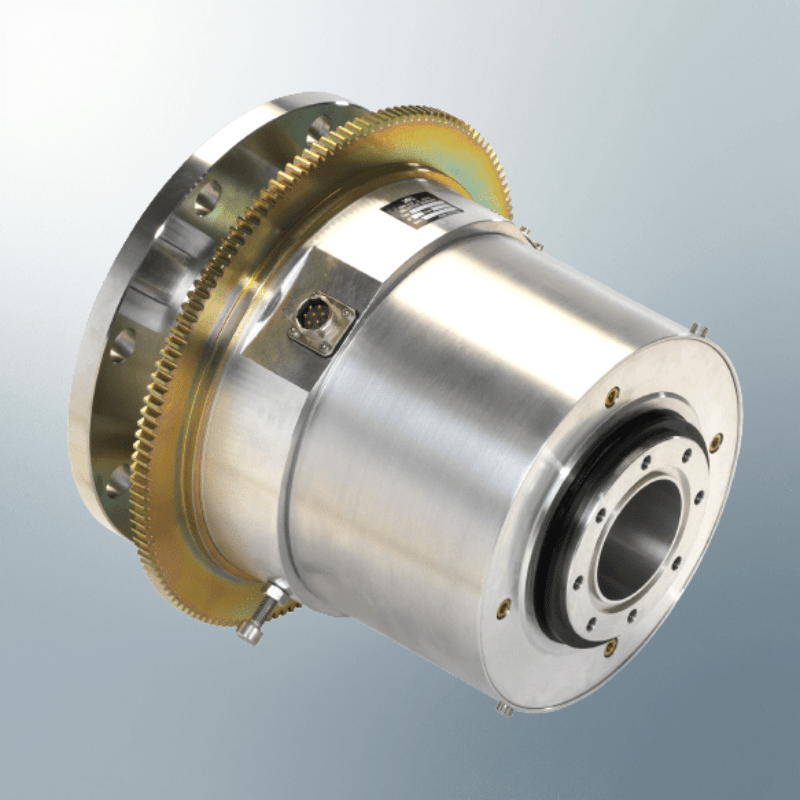

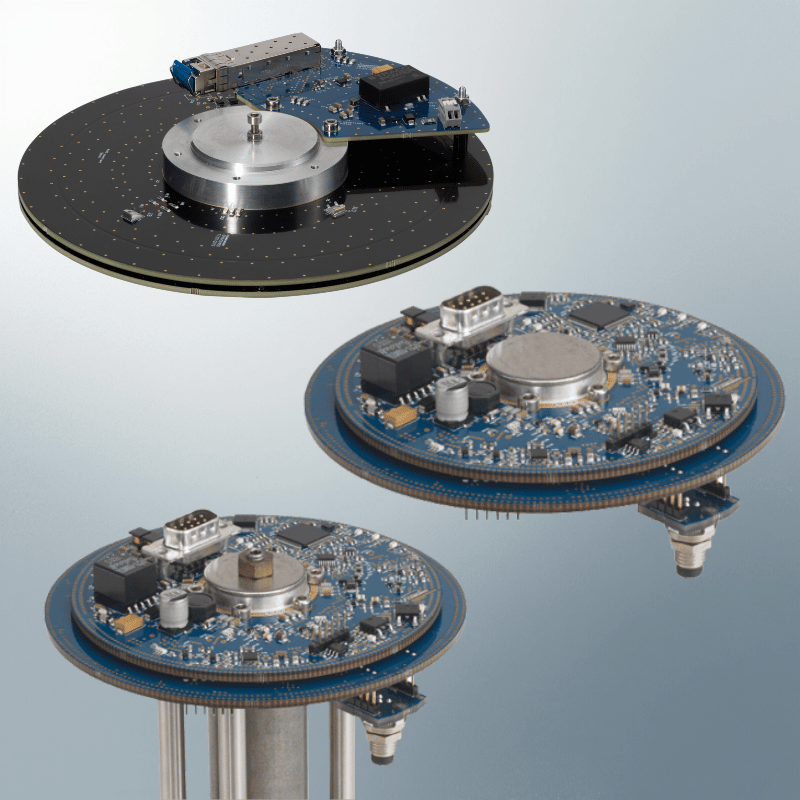

Drawing on its expertise in rotary systems, Everaxis develops custom Contactless Slip Rings, designed to meet the specific constraints of each industrial application.

Everaxis solutions include:

These solutions are:

- modular and plug & play

- compatible with major industrial Ethernet protocols

- designed for continuous operation without maintenance related to contact wear

- suited to demanding industrial environments

Detailed features and configuration options are available on the dedicated product page.

A technology serving modern industrial rotary systems

Contactless Slip Rings are not a universal solution but a targeted technological response to the evolving requirements of rotary systems.

When reliable, continuous, high-speed data transmission is required, especially in demanding industrial environments, contactless technology provides a relevant alternative to traditional mechanical solutions.

By combining contactless technologies, custom design, and historical expertise in rotary interfaces, Everaxis supports industrial clients in developing high-performance, durable rotary systems that meet current and future operational requirements.