In aerospace and aviation, rotary systems – turbines, test benches, or onboard instrumentation – face extreme conditions: high speeds, vibrations, extreme temperatures, and the need to simultaneously transmit power and data.

Therefore, Everaxis’ High Speed Slip Rings range is designed to meet these challenges with reliability, low electrical noise, and long service life. Moreover, this article explains what a high-speed slip ring is, why it is crucial in aerospace, and how Everaxis’ Embedded High Speed Slip Ring is used in demanding applications.

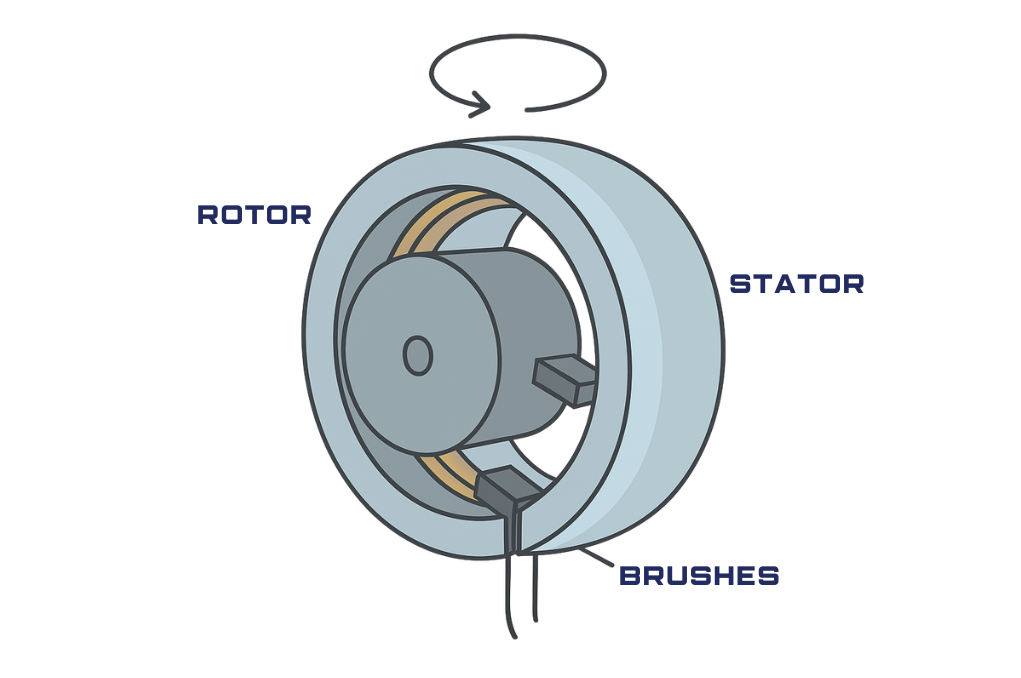

What is a High Speed Slip Ring?

A slip ring is an electromechanical device that allows continuous transmission of power, signals, or data between a stationary and a rotating part. However, in high-speed versions, it must operate at several thousand rpm while maintaining:

- Excellent signal integrity

- Low electrical noise

- Mechanical reliability under centrifugal forces.

Typical features include:

- Contacts in silver, gold, or graphite, or brush fibers depending on design, ensuring conductivity and durability

- Precision or specially balanced ball bearings to minimize vibration and friction torque

- Compact structure with materials suitable for high-speed and high-temperature environments

- Simultaneous power and data transmission in some models

Consequently, these characteristics make high-speed slip rings essential in advanced aerospace systems.

Why High-Speed Slip Rings matter in aerospace?

Extreme Speed, Vibration, and Altitude

In a helicopter rotor, turbine, or aerospace test bench, rotational speeds can reach or exceed 10,000 rpm. Some industrial references even mention speeds of 20,000 rpm or more. As a result, centrifugal forces, imbalances, vibrations, and temperature changes require ultra-robust materials and designs. In fact, these constraints continuously push manufacturers toward increasingly optimized technologies.

Simultaneous power and data transmission

The trend is clear: not only transmitting power (for engines, electromechanical systems) but also data (sensors, instrumentation, onboard systems). Consequently, a high-speed slip ring must ensure uninterrupted data flow, extremely low electrical noise, and signal stability, even at high speed. In addition, the growing amount of onboard instrumentation makes reliability even more critical.

Harsh environments: vibrations, shocks, high temperature

Aerospace applications demand maximum robustness: resistance to high levels of vibration, shocks, extreme temperatures, and even high altitudes. Moreover, some models are available up to 150,000 rpm or designed for severe environmental testing.

Benefits for manufacturers and integrators:

- Ensure uninterrupted transmission in critical rotations

- Reduce failure risk from wear or vibration

- Optimize system performance (torque control, electrical noise, maintenance)

Why Choose Everaxis’ High Speed Slip Rings Range

Everaxis slip rings are engineered for extreme aerospace requirements. Indeed, they offer:

- Speeds up to ≈20,000 rpm (depending on specifications)

- Low electrical noise, high reliability, long service life

- Contacts: silver, gold and/or graphite, low torque, precision bearings

- Designed for high vibration and high temperature environments

- Easy maintenance with interchangeable parts

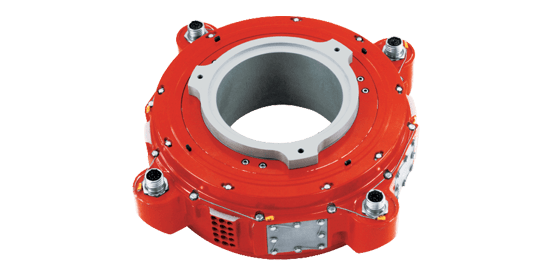

The Embedded High Speed Slip Ring

Everaxis’ Embedded High Speed Slip Ring delivers power and data transfer at up to 20,000 rpm, optimized for aerospace applications such as:

- Helicopter de-icing systems

- Helicopter and aircraft onboard instrumentation

- Rotor/dynamic test benches where high-speed rotation and data transmission are critical

- Applications constrained by weight, size, and power (SWaP-C)

Key technologies:

- Gold-to-gold contact technology for long-term reliability and uninterrupted transmission

- Silver/graphite contacts for specific environments

- Multiple contacts per circuit for high-quality transmission

- Proven materials with over 40 years of experience across various aircraft

Advantages for engineers and integrators:

- Compact and lightweight for easy integration

- Modular and interchangeable design for simplified maintenance

- Proven reliability in extreme conditions

- Reduces operating costs through long life, low torque, and low noise

Integration advice and selection criteria

For an engineer or technical buyer considering the integration of a High Speed Slip Ring, here are some key criteria to check:

- Rated speed (rpm) and safety margin for the actual application

- Type of contacts (gold-to-gold, silver/graphite) and their impact on lifetime and electrical noise

- Friction torque and mechanical balancing to avoid vibrations/losses

- Environmental conditions: temperature, vibration, altitude, shocks – choose a model specified for these conditions

- Capacity for simultaneous data (signal, digital, fieldbus) and power transmission

- Weight, size, and volume – especially critical in aerospace due to SWaP-C constraints

- Maintenance: ability to interchange parts, documentation, spare part availability

- Total cost of ownership: purchase + maintenance + lifespan

To explore all technical details, configuration options, and request a personalized study,