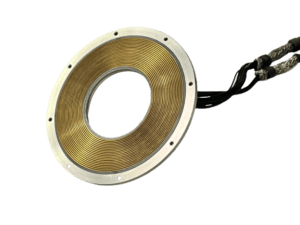

Dense Signal Design Slip Ring Separates

Dense Signal Design Slip Ring Separates are modular rotary transmission units. They handle a large number of low-level signal circuits while keeping the design compact and lightweight. Unlike integrated or…

Separates are typically rings and insulation material assembled on an axis along with separate contact brushes. They are usually designed with flying leads. Once integrated, they provide electrical contact between stationary and rotating parts of a slip ring assembly. They use bearings from the host system and provide a more compact and economical solution than self-contained Slip Rings. The coupling of these items requires technical skills from the OEM and is suitable for applications that have tight mechanical requirements.

Typical uses are for missile applications or any application where packaging is tight. Radar antennas and applications integrating additional technologies (RF, optical, fluids, etc.) also use Slip Ring Separates.

Slip Ring Separates are built to the same standards as self-contained Slip Rings. They are customized to meet the technical requirements of OEMs.

LE PLESSIS ROBINSON

5, avenue Denis Papin

BP 36

92350 Le Plessis Robinson

France

Naples

3030 S Horseshoe Drive Suite 300,

Naples, Florida,

USA 34104

ANNEMASSE

18, rue de Montréal

B.P. 439 Ville-la-Grand

74108 Annemasse Cedex

France