Rotating solutions

Discover some of the solutions we have custom engineered for our clients’ specific projects. We will be happy to assist with yours.

France Annemasse

Designing a 100% custom-made Slip Ring

for high-speed bottling machines

What our customer needed

A manufacturer of high-speed blowing machines for the bottling industry needed help with designing a specific solution – starting from scratch – for a new product line. The need was for a compact Slip Ring, with high data rate and multi-ethernet channels with high EM immunity.

Solution

A highly specialized design, fully made-to-measure and adjustable, co-designed with our customer, thanks to:

•In-house design and development of electronic contactless features and early test campaign at the customer site.

•Trade studies with different scenarios, to help the customers define their specifications.

•An innovative solution, able to increase data speed and optimize size with strong immunity and optical output.

Benefits

New market opportunities for our industrial customer, thanks to a whole new generation of machines

Sweden Kista

Implementing early stage R&D

in strong interaction with our customer’s teams

What our customer needed

Our customer needed to clarify the product concept and pre-RFP specifications of an optimized replacement Rotary Joint assembly, for an existing radar system.

Solution

EVERAXIS provided specialist advice for the definition of the initial need and proposed an agile method by iterations with the customer’s R&D teams, in order to identify the specifications. The main steps were :

•Initial interactions even before there was a program name

•Trade studies for c.2 years prior to RFP: 8 trade study iterations and co-development of specifications

•Significant involvement in concept stage through advanced in-house integration capabilities

Benefits

A breakthrough design and solution, thanks to the ability to optimize size, weight and power through vertical integration.

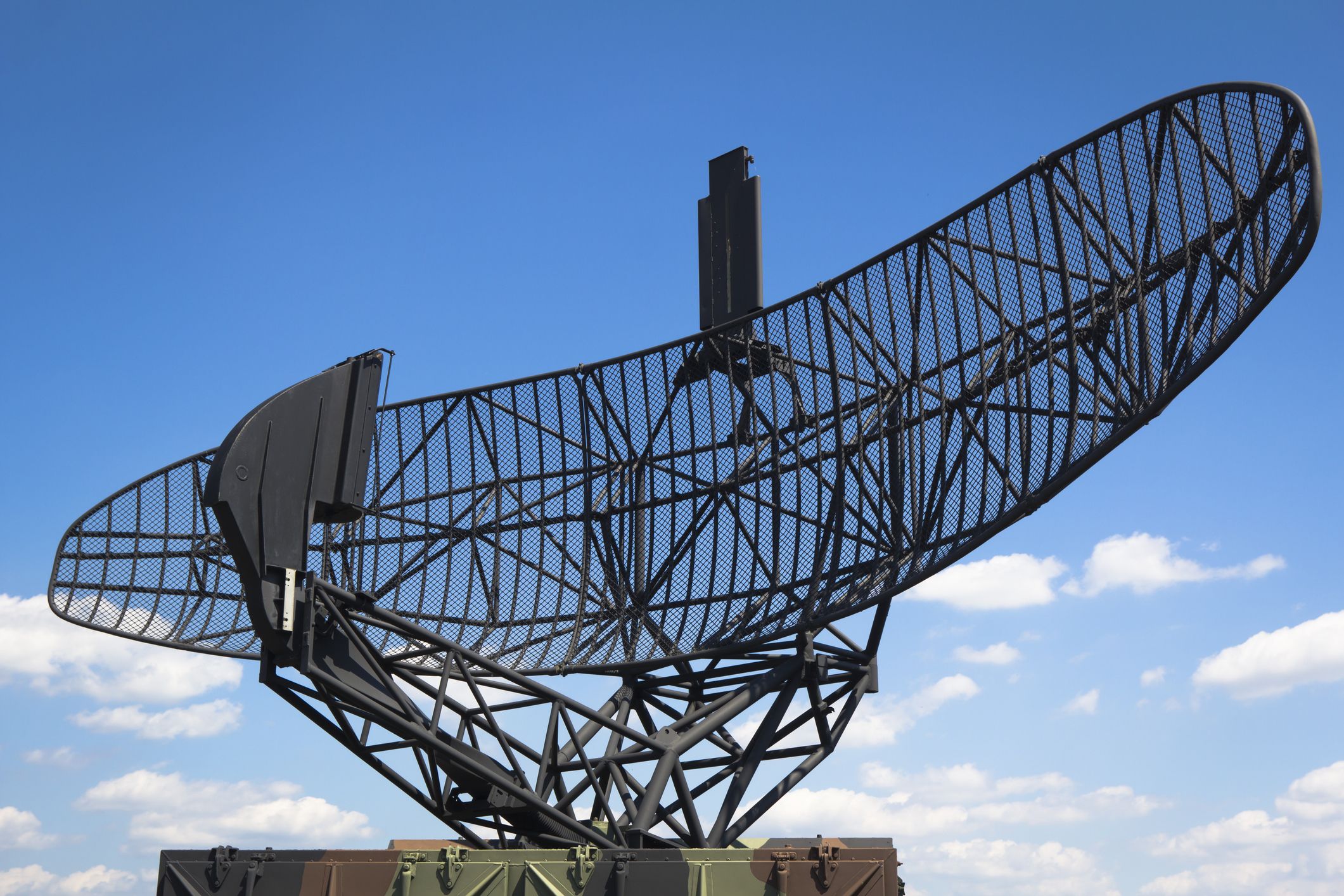

Sweden Kista

Custom Rotary Joints for extreme conditions

Designing a maintenance-free Radar Rotary Joint, for installation beyond the Arctic Circle

What our customer needed

Our customer wanted to ensure continuous operation for a radar installation in the very northern part of Norway, a region characterized by its extreme winter temperatures that can descend as low as -51°C.

Solution

High-end material and design solution, resulting in a no-maintenance high-performance Rotary Joint.

Benefits

- A long life expectancy with maximum endurance in extreme climate.

- A minimized total cost of ownership.

USA Naples

Designing rotating systems for extreme conditions of use

Shock, vibrations, high-intensity, extreme temperature variations, extreme speed … in high-risk environments

What our customer needed

RAYTHEON needed high-performance Slip Rings for its new LTAMDS program (Lower Tier Air and Missile Defense Sensor) for the US Army. The system is the replacement for the Patriot radar, which has hundreds of systems deployed throughout the world. The LTAMDS is a missile defense system that defends against conventional – but also hypersonic – missile attacks.

Solution

EVERAXIS Slip Rings were selected by RAYTHEON for their resistance under extreme temperature variations, and considerable shock and vibration intensities.

Benefits

Proven long life, resulting in reduced maintenance cycles, with swift and responsive customer support.

USA Naples

Integrating and assembling sophisticated Rotating Systems

Providing high-reliability Slip Rings and Rotary Joints for an OMFV

What our customer needed

Their need was to integrate multiple and complex technologies (RF, Optic Fiber, Encoder, Fluid Joint) in the same rotating unit, with the highest level of reliability in transmission, in an OMFV (Optionally Manned Fighting Vehicle).

Due to new turret requirements, modern turret systems increase the complexity of rotating systems and therefore place greater demand on them.

Solution

A Rotating System optimized for multi-functionalities and multi-technology integration, while being capable of enduring extreme shock environments: The system must operate in full capacity while the weapons are being fired.

Benefits

- Optimized SWaP (Size, Weight and Power)

- Proven long life, resulting in reduced maintenance cycles, with swift and responsive customer support.