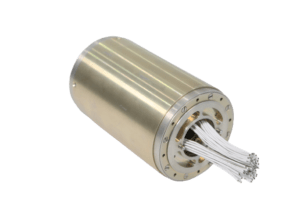

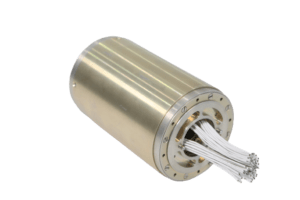

Space applications require cutting-edge Slip Rings that ensure outstanding reliability faced with external vibrations and shocks during launch. When in orbit, the Slip Ring must be capable of handling extreme temperatures, radiation and vacuum conditions.

Vacuum Slip Rings use special materials, thermal treatments and manufacturing processes such as welding and brazing in clean rooms, in order to avoid outgassing on potential surrounding optics while operating safely without maintenance for years. Special care is taken in terms of electrical insulation between channels and overall embedded weight.